Products

Two, the carat tube performance of the carat tube products.

1. Excellent physical properties. HDPE has good rigidity, strength, flexibility and creep resistance, and HDPE has better hot-melt bonding properties, which is conducive to the installation of plastic pipes.

2. Corrosion resistance, long service life, in China's coastal areas, high groundwater level, land moisture, and PE pipe can withstand the erosion of a variety of chemical media, do not need anti-corrosion treatment. In addition, the service life is 100 years.

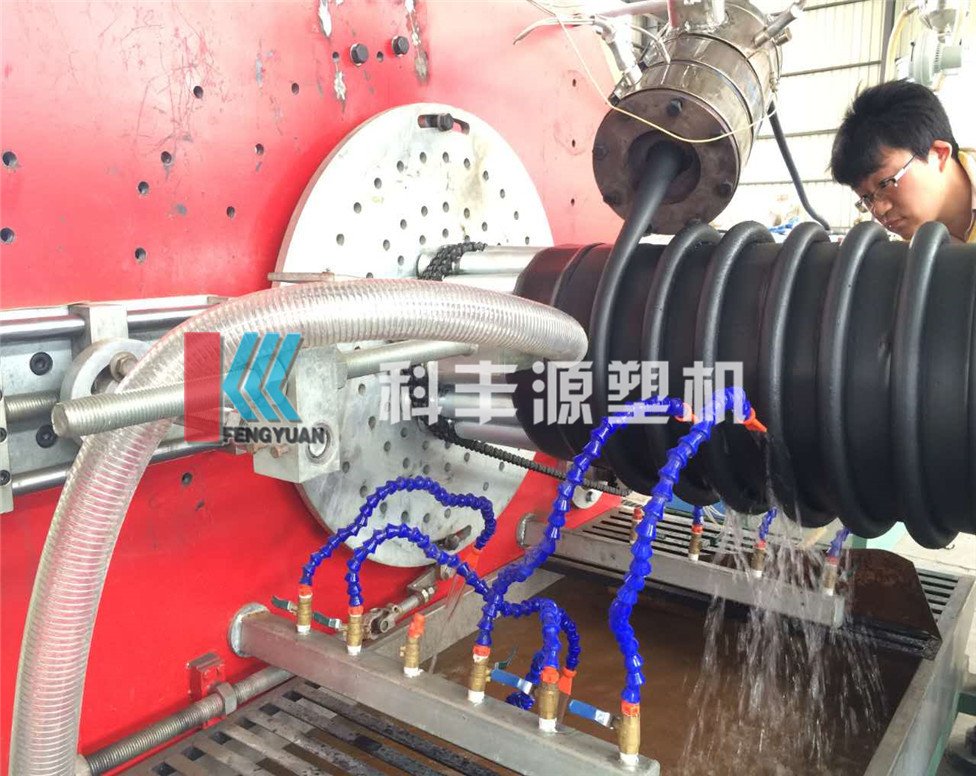

3. Hot-state winding forming weld quality is high. The flat and cladding strips extruded from the extruder die in the melting state are wound evenly on the heated drum mold according to the predetermined position to ensure the weld quality of the structural wall pipe. The pipe is cooled by air and the material is cooled evenly. Especially in the structural design, the welding seam of the plain belt is covered by the support pipe coated by the material belt, which improves the overall anti-external pressure ability of the product. Horizontal layer of pipe and strengthening layer are welded in melting state, the weld quality is high, there is no internal stress, and the overall strength of pipe is high.

4. Toughness and flexibility. PE pipe is a kind of high toughness pipe whose elongation at break is more than 500. It has strong adaptability to uneven settlement and dislocation of pipe foundation and good seismic resistance. Therefore, PE pipe is suitable for seismic risk areas. Practice around the world has proved that PE pipe has good seismic resistance. It is reported that PE pipes and water supply pipes are not damaged in the 1995 Kobe earthquake in Japan. In addition, the flexibility of PE pipe is that PE pipe can be coiled (especially small PE pipe diameter), reducing a large number of connection pipe fittings. The direction of PE pipe is easy to change according to the requirements of construction method. During construction, it is possible to bypass obstacles in the allowable bending radius of the pipe and reduce the difficulty of construction.

5. Ring flexible plastic pipe belongs to flexible pipe. Under external pressure load, the mechanism of flexible pipe and rigid pipe is completely different. Flexible pipe can deform greatly before it is destroyed by compression, while rigid pipe can not deform greatly before it is destroyed by external pressure. When the rigid pipe is subjected to external pressure, the load is transmitted completely through the pipe wall to the bottom of the pipe bed, and the bending moment is generated in the pipe wall. With the increase of pipe diameter, the bending moment and stress of the pipe wall increase sharply, so the large diameter concrete drainage pipe often needs reinforcement: while the flexible pipe deformation-lateral expansion before compression failure, pipe material. The surrounding backfill soil can prevent the deformation and expansion of flexible pipe, and the external pressure load is transferred and distributed to the surrounding backfill soil. Therefore, under the same external pressure load, the stress in the flexible pipe wall is smaller, and it acts with the surrounding backfill under the load. Therefore, the plastic buried drainage pipe does not need the same strength and stiffness as the rigid concrete pipe, under a reasonable stiffness, it can completely meet the requirements of use, which has been proved by the practice of European developed countries.

6, the circulation capacity is large and the economy is cost-effective. The inner wall of PE pipe is smooth without scaling. The ratio of surface equivalent to roughness of PE pipe is 1/20 of that of steel pipe. The flow capacity of PE pipe with the same diameter, length and pressure is about 30% larger than that of steel pipe, so the economic advantage is obvious. Compared with the metal pipeline, PE pipeline can reduce the project investment by about one third (the diameter of 200 mm or more pipe cost is slightly higher), can coil the small diameter pipe, can further reduce the project cost.

7, good sealing performance. PE pipe itself is welded (hot melt or electric melt), essentially guaranteeing the interface material, structure and tube itself identity, to achieve the joint and pipe material. The tensile strength and blasting strength of the interface are higher than those of the tube itself, and can resist the circumferential stress axial stress caused by the internal pressure. Therefore, there is no danger of leakage caused by contact distortion compared with rubber ring connection or other mechanical joints, and the sealing performance is very good.

8. Excellent installation performance, pipeline connection using embedded fuse in the socket with the material socket fuse connection technology, high quality connection. It can achieve 100 no leakage, ensuring the same life and operation of the pipeline system. At the same time, because the product is lighter than other pipe materials under the same application conditions, easy to transport, convenient and quick construction, can reduce the construction cost, in the scope of application, without the need for concrete cushion and concrete pipe foundation groove qualified can be directly laid pipe, basically achieve side excavation, side pipe, side backfill, simplified the construction process Preface shortens the construction period. In engineering acceptance, closed-air test is used instead of closed-water test, which not only reduces the acceptance speed, but also saves the complicated work and a large number of test costs in closed-water test.

9. Good resistance to stress cracking: PE pipe has low notch, high shear strength of the different resistance to trace resistance, environmental stress resistance is very prominent.

10. Low temperature impact resistance is good: PE tube low temperature embrittlement temperature is extremely low, can be used in - 60 degrees Celsius temperature range. However, in the northern part of China, in winter when the field laying of polyethylene buried water supply, summed up a lesson is that below zero is not suitable for paving construction, because polyethylene pipe is easy to crack.

Top